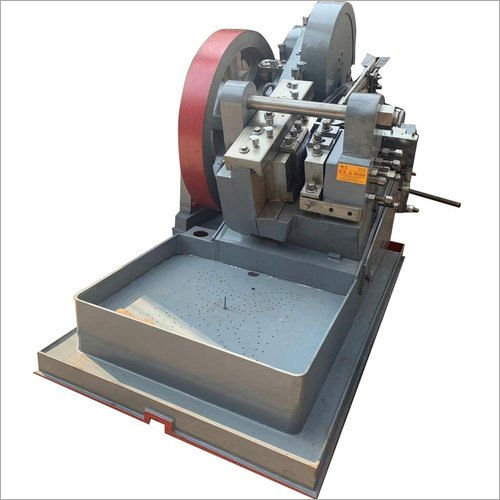

INDUSTRIAL ROLLING MACHINE

Price 1550000.0 INR/ Unit

INDUSTRIAL ROLLING MACHINE Specification

- Accuracy

- 1000 gm

- Voltage

- 25 Megaampere ( MA)

- Motor Power

- 1440 Kilowatt (kW)

- Production Capacity

- 30-35 Pcs/hr

- Lubricating System

- YES

- Country Of Origin

- INDIA

- Frequency

- 1440 Milihertz

- Power Rating

- 6500

- Operating Temperature

- 100 Fahrenheit (oF)

- Model No

- BSTRM-25

- Features

- RELIABLE

- Connectivity Options

- ELECTRICITY

- Machine Type

- SEMI-AUTO

- Noise Level

- 1000 db

- WorkingSpeed

- 30-35

- Control System

- Semi-Automatic

- Product Type

- Cutting Machine

- Technology

- Other

- Power Source

- Electricity

- Operating Type

- Semi Automatic

- Power

- 9000 Megaampere ( MA)

- Pressure

- 9000 kgf/m2

- Surface Treatment

- Painted

- Dimension (L*W*H)

- 150 Millimeter (mm)

- Weight (kg)

- 9000 Long Ton

- Color

- GREEN

- Warranty

- 1 YEAR

- Usage & Applications

- IRON

INDUSTRIAL ROLLING MACHINE Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash on Delivery (COD), Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 1 Unit Per Month

- Delivery Time

- 1 Week

- Sample Available

- No

- Sample Policy

- Free samples are available

- Main Domestic Market

- All India

About INDUSTRIAL ROLLING MACHINE

SEMI AUTOMATIC THREAD ROLLING MACHINE- Full Automatic Design with Speed N Efficiency.

- Less Vibration

- Large Capacity

- High Efficient.

- Easy to Operate and Adjustment.

- Stable Quality.

High Performance and Practical Usage

The BSTRM-25 Rolling Machine is engineered to deliver outstanding performance with reliable output for iron processing industries. Its semi-automatic design provides a balance between user control and productivity, making it well-suited for medium to high-volume operations. Featuring a production rate of up to 35 pieces per hour, this machine ensures operation with minimal downtime, thanks to its robust lubricating system and painted finish for longevity.

Efficient Control and Safe Operation

With semi-automatic controls and electric connectivity, this rolling machine simplifies complex rolling processes. Operators benefit from precision engineering, a manageable noise level, and built-in safety features. Its 1-year warranty and sturdy construction provide peace of mind for continuous industrial use, making it a dependable choice for manufacturers seeking efficient, long-lasting machinery.

FAQs of INDUSTRIAL ROLLING MACHINE:

Q: How does the semi-automatic control system of the BSTRM-25 enhance operation?

A: The semi-automatic control system allows operators to manage the rolling process with a combination of manual oversight and automated functionalities. This results in consistent output, easier handling, and improved safety during iron processing.Q: What materials is the BSTRM-25 Industrial Rolling Machine primarily used for?

A: The BSTRM-25 is specifically designed for rolling iron, delivering precision and uniform output ideal for various industrial applications involving ferrous metals.Q: When is it beneficial to use a semi-automatic rolling machine instead of a fully manual or automatic one?

A: A semi-automatic rolling machine like the BSTRM-25 is beneficial when you require some manual control for customization while still enjoying the efficiency and repeatability of automated systems, making it suitable for medium-scale operations.Q: Where should the BSTRM-25 Rolling Machine be installed for optimal performance?

A: It is recommended to install the BSTRM-25 in an industrial setting with adequate electrical supply, proper ventilation, and stable flooring to accommodate its weight and dimensions for safe, continuous operation.Q: What is the standard process for operating the BSTRM-25 Rolling Machine?

A: Begin by ensuring the machine is connected to a reliable electric source. Set the required parameters via the semi-automatic control panel, lubricate as instructed, feed the iron, and monitor the output, ensuring safety protocols are followed throughout the process.Q: What are the main benefits of using the BSTRM-25 Rolling Machine in iron processing industries?

A: Key benefits include high production capacity, robust durability, reduced manual effort, consistent output quality, and support from a 1-year warranty, making it a reliable investment for manufacturers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thread Rolling Machine Category

Automatic Thread Roll Machine

Price 400000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Fully Automatic

Power Source : Electricity

Weight (kg) : 2400 Kilograms (kg)

Color : RED

240V Automatic Roll Thread Machine

Price 900000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Other, PLC Controlled

Power Source : Other, Electric

Weight (kg) : 1200 kg

Color : Blue & Silver

FLAT DIE THREAD ROLLING MANUAL

Price 1549997.0 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Manual

Power Source : Electricity

Weight (kg) : 8000 Kilograms (kg)

Color : WHITE

Flat Die Thread Roll Machine

Price 350000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : SemiAutomatic

Power Source : Electricity

Weight (kg) : 3200 Kilograms (kg)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free