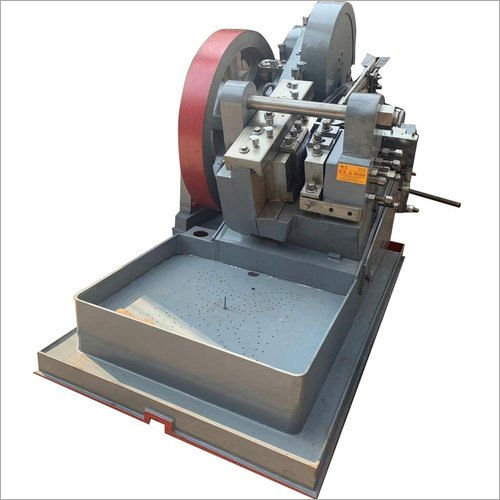

240V Automatic Roll Thread Machine

Price 900000 INR/ Unit

240V Automatic Roll Thread Machine Specification

- Drive

- Electric Motor

- Operating Temperature

- 5C - 45C

- Cooling System

- Water Cooled

- Machine Type

- Automatic Thread Rolling

- Frame Type

- Rigid Frame

- Model No

- ART-240V

- Accuracy

- 0.01 mm

- Voltage

- 240V

- Noise Level

- 75 dB

- Power Rating

- 4 kW

- WorkingSpeed

- 55 RPM

- Lubricating System

- Automatic Centralized Lubrication

- Frequency

- 50 Hz

- Connectivity Options

- Standard Electrical Connection

- Production Capacity

- 300 pcs/hr

- Motor Power

- 4 kW

- Control System

- PLC Controlled

- Product Type

- Automatic Roll Thread Machine

- Technology

- Rolling / Threading

- Power Source

- Electric

- Operating Type

- Automatic

- Power

- 4 kW

- Pressure

- Adjustable

- Surface Treatment

- Polished

- Dimension (L*W*H)

- 1500 x 1050 x 1400 mm

- Weight (kg)

- 1200 kg

- Color

- Blue & Silver

- Usage & Applications

- Thread rolling on metal rods and bars

240V Automatic Roll Thread Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About 240V Automatic Roll Thread Machine

240V Automatic Roll Thread Machineis designed for facilitating rolling and threading of foundation bolts. Made up of top-grade cast iron structure and components & parts with advanced technology, it is sturdy construction, convenient to operate, and suitable for wire diameter of 4-6mm. It performs with production speed of 90-95 pcs/min, and is powered by 2HP motor.

Specification

|

Wire Diameter |

4-6 mm |

|

Country of Origin |

Made in India |

|

Usage/Application |

Foundation Bolt |

|

Material |

CI Castings |

|

Automation Grade |

Automatic |

|

Power |

2Hp |

|

Voltage |

240V |

|

Brand |

B S & Sons |

|

Capacity |

90-95pcs/mint |

High-Performance Thread Rolling

Achieve exceptional speed and accuracy in threading with the 240V Automatic Roll Thread Machine. Engineered for efficiency, it boasts a production rate of 300 pieces per hour and maintains thread accuracy within 0.01 mm. With its 4 kW electric motor and advanced PLC control system, this machine is tailored to meet the rigorous demands of modern manufacturing.

Safety and Versatility Combined

This roll thread machine prioritizes user safety by incorporating features like an emergency stop button and safety guards, ensuring secure operation in industrial environments. Its compatibility with input materials ranging from 10 mm to 30 mm in diameter, along with quick-change fixtures and both manual and automatic adjustment options, provides unmatched flexibility for operators.

Easy Maintenance and Robust Construction

Designed for long-term performance, the machine includes accessible panels for effortless maintenance. Made from polished stainless steel and housed in a rigid frame, it withstands heavy-duty usage. The automatic centralized lubrication system and water-cooled technology minimize operational interruptions, while its floor-mounted design ensures stability and durability.

FAQs of 240V Automatic Roll Thread Machine:

Q: How does the automatic roll thread machine operate for different thread dimensions?

A: The machine supports thread diameters from 4mm to 30mm and lengths up to 100mm. Operators can select manual or automatic adjustment modes through the digital display, making it easy to set precise rolling parameters for each job. The quick-change fixture further streamlines adaptation to various thread sizes.Q: What safety mechanisms are integrated into the machine for operator protection?

A: To ensure safe operation, the machine is equipped with an emergency stop button and safety guards. These features help prevent accidental contact during operation, and the sturdy frame further enhances protection in industrial environments.Q: When should routine maintenance be performed, and how accessible are key components?

A: Routine maintenance is recommended as per the machines operating schedule to maintain performance and longevity. Easy-access panels facilitate quick inspection, lubrication, and part replacement, minimizing downtime and ensuring reliable operation.Q: Where is the optimal installation environment for this machine?

A: The machine is designed for floor-mounted installation in well-ventilated areas with ambient humidity not exceeding 85% and temperatures between 5C and 45C. A stable surface ensures minimal vibration and optimal operational safety.Q: What is the process for changing rollers or fixtures on this machine?

A: The machine features a quick-change fixture system, allowing operators to swap rollers or fixtures efficiently. This can be done with the included tool kit, reducing downtime and maintaining consistent production schedules.Q: How does the machine benefit production efficiency and output quality?

A: With a processing capacity of 300 pieces per hour and accurate thread forming within 0.01 mm, the machine greatly enhances production efficiency. Features like automatic lubrication, water cooling, and PLC control ensure consistent output quality while minimizing wear and energy consumption.Q: What are the usage applications of this automatic roll thread machine?

A: This machine is ideal for threading metal rods and bars in industrial manufacturing settings. It is well-suited for suppliers, manufacturers, and workshops involved in metal fabrication, construction component production, or any process requiring high-precision threads at scale.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Thread Rolling Machine Category

BOLT THREAD ROLLING MACHINE

Price 1350000.0 INR / Piece

Minimum Order Quantity : 1 Piece

Control System : SemiAutomatic

Voltage : 15 Teraampere (TA)

Weight (kg) : 6500 Kilograms (kg)

Power Source : Electricity

Flat Die Thread Rolling Machine

Price 355000.0 INR / Unit

Minimum Order Quantity : 1 Kilograms

Control System : Fully Automatic

Voltage : 10 Statampere (sA)

Weight (kg) : 2500 Kilograms (kg)

Power Source : Electricity

INDUSTRIAL ROLLING MACHINE

Price 1550000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : SemiAutomatic

Voltage : 25 Megaampere ( MA)

Weight (kg) : 9000 Long Ton

Power Source : Electricity

Industrial Roll Thread Machine

Price 751000 INR / Unit

Minimum Order Quantity : 1 Unit

Control System : Other, Manual Lever & Electrical Panel

Voltage : 415 V (Three Phase)

Weight (kg) : 1850 kg

Power Source : Other, Electric

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free